Innovation and digital review

Continuous innovation at ACWA Power to scale up at speed

Innovation is a key driver of ACWA Power's success and has been since the company’s inception 20 years ago. It gives us competitive advantage, creates value, and is a vital ingredient in energy transition because it enables us to scale up at speed. It makes our plants more energy efficient and delivers world‑beating, low tariffs for offtakers and for the communities we serve.

ACWA Power has executed its innovation roadmap (2021–2024) successfully, resulting in USD 85 million nominal value creation, 31 patent applications, and achieving a strong position as a technology leader and innovation champion.

ACWA Power uses proprietary processes, open innovation and exclusive partnerships, and focuses on:

- 100% renewable desalination at a low, competitive cost, aiming for 100% renewable power supply at all its plants rather than using conventional grid power

- Green hydrogen at low cost, using disruptive processes, to compete successfully with grey hydrogen

- Large scale 24 hours+ electricity storage at low cost to compete with CCGT

- Fully automated operation and maintenance of renewable energy and desalination plants, leveraging advanced AI capabilities

Innovation Journey 2021–2024: Milestones

Examples of ongoing projects

Sakaka PV IPP

Taweelah IWP

Rabigh 3 IWP

Collaborative, open innovation based on partnerships

ACWA Power is the ideal partner for governments, offtakers and the entire innovation ecosystem seeking to implement energy and water projects at scale, given its track record and its latest advances in technology and digitalisation to deliver optimal outcomes. ACWA Power collaborates with technology developers and R&D partners in KSA and around the world. Through strategic partnerships and co‑development initiatives, we provide a unique platform for the development and commercialisation of innovative technologies. The Company has open innovation partners, including Dupont, the King Abdullah University of Science and Technology (KAUST), Longi, Saudi Aramco, and Shanghai Electric.

Foundational R&D and innovation work

ACWA Power has a culture of ingenuity and a spectrum of initiatives and activities to boost innovation:

- Ideation initiatives, internally and through open innovation idea generation campaigns

- Technology watch across desalination, renewable energy, energy storage, CCUS, microgrid, and hydrogen sectors

- Operational performance improvement projects in desalination, CCGT, solar, wind, BESS

- Pilot testing of key equipment and O&M technologies in desalination, solar, BESS

- Engage early‑stage startups and scout breakthrough technologies ahead of competitors

- Test, scale, and secure limited‑time exclusive access for ACWA Power to gain a competitive edge

- Development or acquisition of simulation models

- Innovation management/roadmap management

- Intellectual property management

- Networking and regular communication

- AI deployment in context with technology optimisation, or ehnancements. Deployed ML algorithm years ago in some projects

Innovation initiatives in 2024

ACWA Power attends and hosts conferences and events throughout the year, in KSA and internationally, and this provides excellent opportunities for discussion and collaboration with internal and external innovators. The Company hosted ‘Innovation Days’ in January at KAUST, collaborated with Africa Energy Indaba on the 2024 ‘Innovation Challenge’, and attended industry and technology conferences in Europe and Asia.

ACWA Power’s China Innovation Centre, Pudong, Shanghai

As an important element in the Company’s expansion in China, a key growth market, ACWA Power has established an innovation centre, which includes an R&D and PV laboratory with a testing capacity of 16,500 modules/year, offices and one conference facility. The centre opened in January 2025, has 31 staff, and has the Chinese certifications CNAS, TUV and UL.

ACWA Power is at the forefront of integrating AI across our technologies to drive optimisation at every level

Some of our awards in 2024

Digital transformation: powering the future of energy and water

Digital as a strategic enabler

In an era of rapid technological advances, ACWA Power is embedding digital transformation across its entire value chain. By integrating AI, automation, and data intelligence, we are unlocking new efficiencies, enhancing sustainability, and strengthening decision‑making. Digitalisation is not just an initiative, it is fundamental to our business strategy, enabling us to drive smarter operations, optimise resources, and empower our people.

“AI is not just about automation, it’s about unlocking new possibilities. By leveraging its power, we are redefining the future of sustainable energy and water.”Bart Boesmans, Chief Technology Officer

“AI is not just about automation, it’s about unlocking new possibilities. By leveraging its power, we are redefining the future of sustainable energy and water.”Bart Boesmans, Chief Technology Officer

Digital at a glance

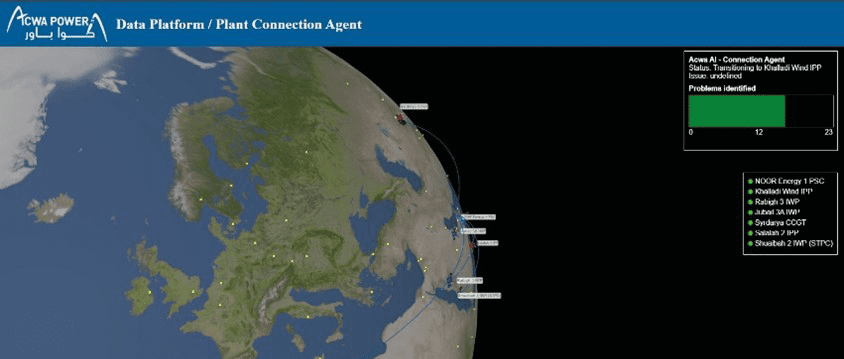

Multiple power plants connected in real time

Digital transformation in action: operations, technology and people

Digital transformation at ACWA Power is centred around three key areas: operations, technology and people. These areas ensure we leverage advanced solutions to enhance performance, strengthen decision‑making, and equip our workforce with the skills to navigate the digital future.

Operations: optimising performance with digital technologies

Operational excellence is at the heart of our digital strategy. By leveraging AI, IoT, and automation, we are streamlining plant operations, enhancing construction efficiency, and optimising procurement, finance, and workforce management. This integrated approach strengthens resilience and ensures long‑term sustainability.

Key digital transformations across operations

- AI‑driven Operations & Maintenance (O&M): includes performance monitoring and predictive maintenance powered by thermodynamic & data science models, AI and IoT to optimise performance, reduce unplanned outages and extend equipment lifecycles.

- Smart construction and project management: digital project tools to improve planning, resource allocation, and execution, ensuring timely and cost‑effective project delivery.

- Intelligent supply chain and procurement: automated forecasting and supplier integration to optimise inventory, reducing lead times and operational risks.

- Finance and workforce optimisation: intelligent automation to enhance financial planning, governance, and workforce agility.

Through data‑driven insights and digital automation, we are creating a more connected, agile, and optimised operational framework, reinforcing our leadership in the energy sector.

Technology: AI and advanced analytics at scale

AI and data analytics are transforming our business, enabling real‑time insights and predictive decision‑making. By integrating AI‑driven solutions across our operations, we are optimising efficiency, reducing downtime, streamlining workflows, and maximising asset performance.

Key AI‑enabled initiatives

- Real‑time operational insights: machine learning and digital twin models within our MPC (Monitoring & Prediction Centre) platform provide analytics that drive performance optimisation.

- Secure generative AI: deployment of multiple open LLMs (Large Language Models) within a protected ecosystem to enhance productivity while safeguarding data.

- AI digital Innovation Lab: a dedicated environment to develop, test, and scale AI solutions for industrial applications.

- Copilot for smarter workflows: Microsoft Copilot empowering employees with AI‑driven automation and decision‑making support.

We focus on expanding AI adoption, strengthening predictive and performance capabilities, and embedding intelligence into every layer of our operations to drive efficiency and sustainability.

People: empowering teams for a digital future

Digital transformation succeeds when people embrace change. We prioritise upskilling and structured change management to ensure our workforce is equipped to leverage digital tools and drive innovation.

- Upskilling and digital capability building: our employees gain the expertise needed to adopt and apply new technologies through targeted training, coaching, and skills development programmes.

- Change management for seamless adoption: we enable smooth transitions and minimise disruptions with clear communication, leadership alignment, and hands‑on support.

As part of our commitment to upskilling, we offer continuous opportunities tailored to employees’ needs and our strategic goals.

Looking ahead: scaling digital innovation

As we continue our digital evolution, we focus on expanding capabilities, enhancing operational intelligence, and maintaining our leadership in the energy and water sectors. Our commitment is to drive sustainable growth by integrating cutting‑edge technology with a people‑first approach. This will enable ACWA Power to become a digital leader in the energy sector through sustained Operational Excellence & Innovation‑based Competitive Edge.

AI Digital Innovation Lab Solutions

The AI Digital Innovation Lab, in ACWA Power’s cloud infrastructure, is a testing ground for new ideas, enabling teams to explore and validate concepts before deciding whether to scale them for industrial use.

For example, the team has developed automation agents capable of detecting and resolving problems in a 3D space. The Plant Connection Agent is the first release of this kind of solution, aimed at automating repetitive and low‑skill tasks performed by people, on a 24/7 basis. This initial solution oversees the connection between the power plant and identifies and fixes any connection issues autonomously, ensuring continuous data transmission to our central hub, saving multiple hours of work each day.

We are also continuously experimenting with digital twin solutions by creating 3D models and a virtual environment to map various values from our IoT system. This prototype leverages Large Language Models (LLM) to create fine details of the solution, thereby reducing costs for the implementation and addressing one of the major limitations of current solutions.

A digital twin for construction, driving process automation for project execution

We have created a digital twin for construction, enabling risk control and mitigation, real‑time project monitoring, stakeholder performance mapping, and the enforcement of quality and turnover package procedures. This approach has successfully shifted the focus from project construction to asset construction, ensuring standardised execution across all technologies and EPC contractors. By digitalising the turnover package, we continue to streamline the transition from project execution to operations, enhancing efficiency and consistency.

Key benefits:

- A single platform with a standardised communication matrix

- Transition from project construction to asset construction

- Standardised project execution across all technologies and EPCs

- Early identification of project health and risks

- Enhanced traceability from construction to operations

- Improved control and tracking of mitigation actions

- Standardised Inspection and Test Plans (ITPs) during construction and commissioning

Business Development Opportunity Management System

The Opportunity Management System has been integrated into ACWA Power’s business development processes, streamlining the investment approval workflow. It enables effective pipeline monitoring and financial metric tracking, ensuring progress control, milestone oversight, and the timely identification of potential risks, to improve efficiency and decision‑making.

Key benefits:

- Real‑time oversight: enables continuous monitoring of business processes, providing stakeholders with immediate visibility into progress and performance.

- Standardised process: a unique approach applied across regions ensures consistency, streamlining operations and improving alignment between teams.

- Streamlined reporting methods: reduces manual effort, accelerating data collection, analysis, and reporting, leading to quicker and more accurate insights.

- Knowledge sharing: facilitates seamless information exchange across regions and teams, enabling more informed and collaborative decision‑making.

- Information retrieval: provides quick access to historical data, offering valuable insights into past bidding strategies and enhancing future decision‑making.

- Workload visibility: offers clear insight into workloads through optimised resource allocation, ensuring efficient management of tasks and responsibilities.

A new HR system, integrated with finance and satellite systems

Established a single, global core HR system for both ACWA Power and NOMAC employees, integrating it with finance systems and all other satellite systems that rely on employee information.

Key benefits:

- Unify policies, workflows, data and user experience for ACWA Power (and NOMAC).

- One true source of truth for staff personal and employment information, enabling clear and reliable reporting.

- A single source that integrates with other systems needing employee data.

- A cleaner and more efficient system landscape.

- Enhanced Manager, HR and employee self‑service, for data visibility and maintenance, time‑off self‑management and approval and employee requests.

- Direct integration towards payroll system for both ACWA Power and NOMAC.